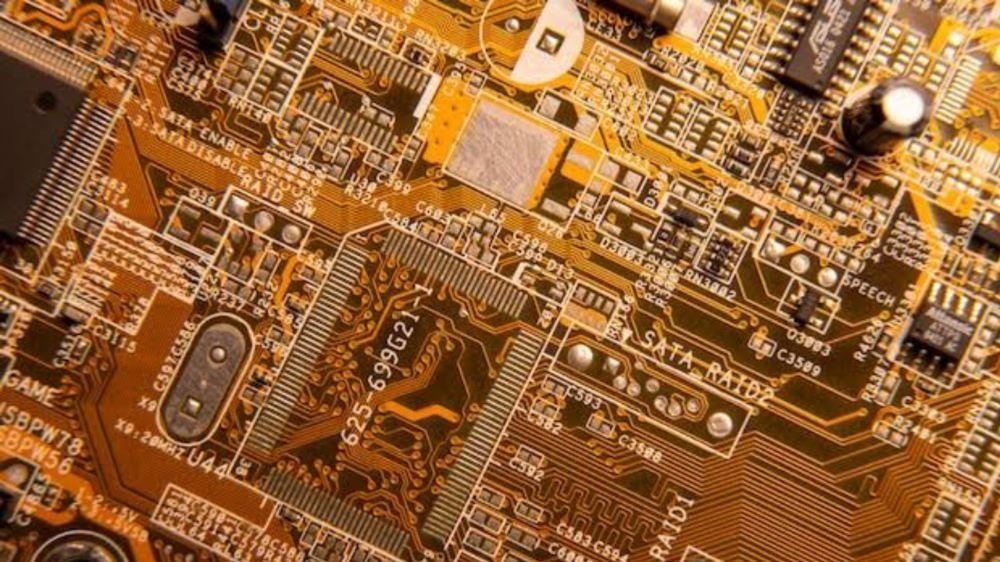

Printed Circuit Boards made the technology easier. Due to the utilization of PCBs, the size of technology products is also reducing over time. Due to these electric wireless connections are possible.

Types of Printed Circuit Board

Following are the major types of the Printed Circuit Board;

- Flex PCBs:

These are flexible circuit boards and these are highly demanding. These Printed Circuit boards have the capability of folding, fittings, twisting, and bending.

Examples: These are mostly used in the fabrication, and formation of LCDs, cameras, medical devices, and automobiles.

- Multilayer PCB

As the name indicates these are the PCBs that have more than two layers in it. It includes more than 2 copper layers such as 4L, 6L, 8L, etc. Its design helps in designing more circuits in less space, high-speed circuits.

Examples: Tablets, computers & Medical equipment

- Rigid PCBs

These PCBs are constructed with the use of solid substrate materials. So these printed Circuit Boards don’t tend to fold or twist. However, these have greater strength.

Examples: MRI systems, X-ray machines, and GPS equipment.

- Rigid Flex PCBs

These are the hybrid types of the PCBs that are designed in a 3D structure. They don’t require any connectors and are lighter as well.

Examples: These are used in medical devices and aerospace.

- Single Sided PCBs

These are the PCBs that are made from a single layer of the substrate & metal layer mostly copper.

Examples: Electronic toys, calculators

- Double Sided PCB

These are quite similar to single-sided PCBs. In that, the substrate is up and down covered with the metal layer. These are small holes that are drilled in the PCB.

Examples: Amplifiers and cell phones

- High Frequency Printed Circuit Board

These types of PCBs are useful in the frequency range of 500MHz – 2GHz. It usually includes polyphenyl ether (PPO) resin, FR4 class fiberglass reinforced epoxy laminates, and Teflon. These are majorly designed to transfer a large volume of data.

Examples: These are used in GPS devices, receivers, filters, amplifiers, and diagnostic equipment.

- IMS (Insulated Metal Base) PCB

It’s known as the thermal management performance of PCB. It has excellent heat-dissipating capacity & high dielectric strength against high voltages.

Examples: LEDs, power equipment, automotive industries

- High-Density Interconnect

It’s a type of PCB that has multiple interconnections with the little spaces. It’s a multi-layer board that has densely routed layers.

Examples: Aerospace, automotive

- Ceramic PCBs

These are less common types of PCBs. These are useful for the high thermal conductivity. Its surface has the heat transfer properties in it.

Examples: Aerospace and defense systems

- Aluminum PCB

The aluminum PCB uses the aluminum substrate in the printed circuit board. These PCBs have excellent thermal conductivity in them. Besides this aluminum is nontoxic and it can be recycled again.

Examples: LED device

Benefits of Printed Circuit Board

Printed Circuit Board is the most important element in technology. The following are the main benefits of PCB:

- Printed Circuit Boards are wisely useful for industries. Many manufacturing companies are focusing on the production of PCBs to utilize them in small and large products.

- The products in which PCBs are installed are turned to expand the lifespan of the products. It provides more ease to the electronic users. Whether the device is a computer, phone, or other item that can be used in any harsh environment.

- When it comes to the cost PCBs are low in terms of costs. Many components can reduce the cost rate of the production of printed Circuit Boards on an industrial level.

- Using the copy tracks the connections of the PCBs are designed. Due to this, there are not going to be any short circuits or loose connections in the PCBs.

- The use of PCB can also reduce the amount of effort for manufacturing technical products.

- Traditional methods for connecting the components took a lot of time. In comparison to the PCB, it will take a few minutes to assemble after completion of the design.

- Without any current carrying wires the PCB is designed in a way to perform all that similar actions. That is also the reason for smaller electronic devices nowadays as compared to the product size in the past.

- Due to the utilization of PCBs, highly complicated and complex types of circuit Boards can be assembled in small packages.

- Using the PCB you can also modify and launch a customized PCB design.

For more detailed information and manufacturing services, visit the One-stop PCB&PCBA Manufacturer.