One distinct factor that shapes the decision to use CNC machining in part manufacturing is its cost. Many manufacturers ask the question, “Is CNC costly?” However, they receive no definitive answer because several factors determine the cost of the manufacturing process.

This article will help you make a decision as it explores CNC machining and explore factors that can affect the cost. Using this article, you can determine if CNC machining is the most cost-effective solution for your needs.

What Does CNC Stand For?

CNC stands for computer numerical control, a technology which allows a pre-programmed computer software to control the movement of a tool. This technology is used in machining of part, hence, the name CNC machining.

CNC machining is a subtractive manufacturing process that involves using a CNC-controlled tool to remove part of a material from a workpiece and form the final product.

How Does CNC Services Work?

CNC services involves using a CNC machine to create parts using specific machining techniques. Here is a detailed outlook of how a typical CNC services work:

Design Creation

The first step is using CAD software to create a 3D CAD model of the part. The model serves as the blueprint for the CNC machine.

Converting Design into CNC Program

The next step is converting the CAD model into a CNC program or g-code using CAM (Computer-Aided Manufacturing) software. The g-code provides step-by-step instructions for the CNC machine.

Setup the CNC Machine

The third step is setting up the machine by installing the necessary machining tools, securing the material (workpiece), and loading the CNC program into the computer. The choice of the CNC machine depends on the machining operation.

Machining

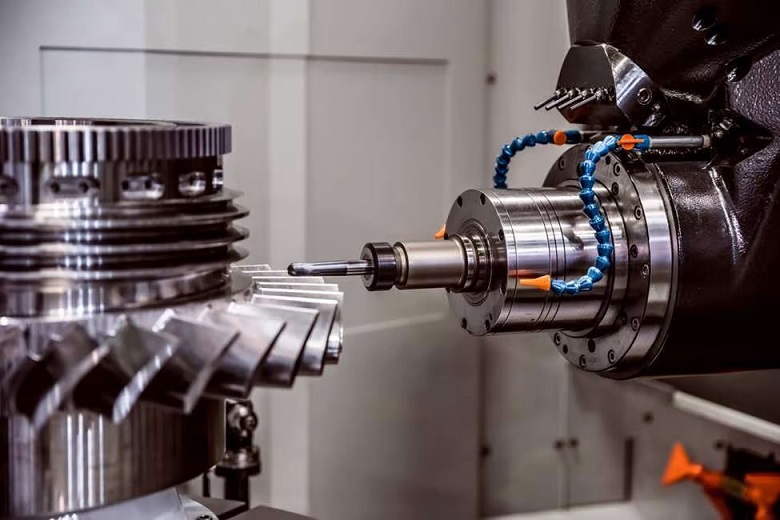

The CNC machine follows the programmed instructions to machine the workpiece. Common machining operation include cutting, drilling, milling, and turning, to shape the material into the desired part.

Quality Control

After machining, inspect the part to ensure it meets the required specifications and tolerances. This may involve measuring tools like calipers, micrometers, and CMMs (Coordinate Measuring Machines).

Common Types of CNC Services

CNC machining encompasses various services, each tailored to specific manufacturing needs. Here are some of the most common types of CNC services:

CNC Milling

CNC milling involves rotating multi-point cutting tools to remove material from a workpiece. It is ideal for creating complex shapes and intricate parts.

CNC Turning

CNC turning uses a lathe to rotate the workpiece while a single-point cutting tool shapes it. This method is excellent for producing cylindrical parts.

Applications: Suitable for creating shafts, bolts, bushings, and other cylindrical components.

CNC Drilling

CNC drilling automates drilling holes in a workpiece with high precision and repeatability. It applies to creating holes in parts, ranging from simple to complex drilling patterns.

CNC Grinding

CNC grinding uses abrasive wheels to remove material and achieve fine finishes on hard materials. It is commonly used in finishing operations on tools, dies, molds, and precision parts grinding.

CNC Laser Cutting

CNC laser cutting employs a focused laser beam to cut or engrave materials with extreme precision. It is suitable for cutting, engraving, and etching metal, plastic, wood, and glass.

How to Estimate CNC Service Cost?

Estimating the cost of CNC services involves considering several factores such as materials, machining time, part complexity, and tooling cost. Here is an explanation on each factors:

Materials

CNC machining is compatible with many materials spanning metals, plastics, and composites. However, the type of material can impact the overall CNC machining cost. For example, metals are generally more expensive than plastics, and high-performance materials like titanium or composites are costly.

Duration of Machining

The machining time depends on the part complexity and machining operation and having a higher machining time can lead to an increase in cost.

Labor Costs

CNC machining requires skilled workforce for a quality and efficient production especially in programming and quality control checks. A skilled workforce will lead to a higher CNC cost, although it depends on the experience and location.

Volume of Production

High-volume production runs can lower the per-unit cost due to economies of scale. Conversely, low-volume or prototype runs may have higher per-unit costs due to the spread of setup and programming costs over fewer parts.

Part complexity

Parts with intricate designs, tight tolerances, or complex geometries will require more sophisticated machining. As a result, this can increase the cost of CNC machining.

Post-Processing Requirements

Additional processes like heat treatment, surface finishing, and assembly can add to the cost. The need for secondary operations like grinding or polishing also affects the price.

Tooling Costs

The cost of specialized tools or custom fixtures for a particular job can be significant, especially for unique or complex parts.

Others

The geographic location of the CNC machine shop and its overhead costs (e.g., electricity, rent) can influence pricing. CNC shops in areas with higher living costs or higher operational costs may charge more.

Is CNC Machining Costly?

The cost-effectiveness of CNC machining depends on the specific application, production volume, material requirements, and precision needed. CNC machining is the preferred manufacturing process for making high-precision, low to medium-volume parts. Other methods offer better cost advantages for high-volume or highly complex parts.

Conclusion

CNC machining high precision, quality, and efficiency makes it the best manufacturing process for several industries such as automotive and aviation. However, its high cost can also be a detriment to its use.

This article introduced the process and talked about several factors that you can understand before choosing it. By understanding and analyzing them, you can make informed decisions about the most cost-effective approach for their needs.

FAQS

Is CNC the Same as CNC Machining?

CNC stands for Computer Numerical Control and is a technology that refers to the use of computerized controls to operate machinery. CNC machining involves using these controls to operate machine tools that cut, shape, and create parts.

Is CNC Difficult?

CNC can be complex, requiring specialized knowledge and skills in CAD/CAM software, understanding machine operations, and troubleshooting issues.

What is CNC in a Workshop?

In a workshop, CNC refers to using computer-controlled machines to perform various manufacturing processes, such as cutting, drilling, milling, turning, and grinding.

Read More: CRM Balitteknologikaret.co.id: Know Everything About